Mobile sheep handling is an integral part of flock health, with just a handful of manufacturers offering them.

A new model to the market promises durability and operator convenience in equal measure. Alex Heath finds out how it performs...

For many sheep farmers a mobile race is a vital piece of equipment to help with flock management.

While the basic premise of different manufacturers' trailer-mounted races is the same, the usability, functionality and crucially build quality all vary. We recently tested the new Alligator Pro 250 from animal husbandry and health specialists Allflex.

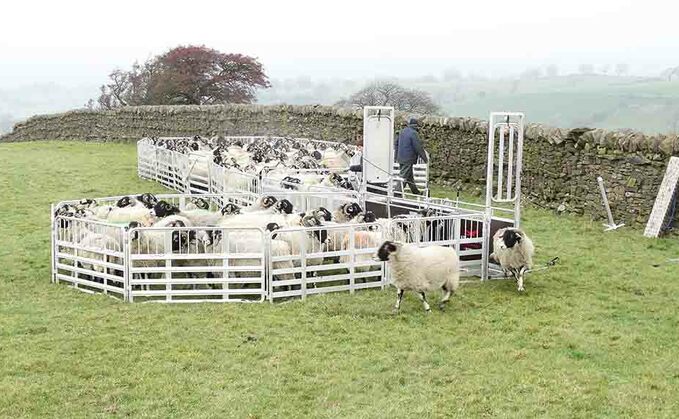

Delivered to Hecklin Farm, Clitheroe, the base for Thomas Binns and family, the new trailer was soon put through its paces with daily tasks on his 2,500 ewes and followers.

Having run several manufacturers' trailers for a number of decades, Mr Binns is well versed in how a mobile race trailer should look and perform. Latterly he has been running Rappa and Prattley units, with varying success across 728 hectares of fell and low land.

The latest Alligator Pro has a plethora of headline features including an electric winch for lifting and lowering, guillotine gates front and rear and a jockey wheel for ease of attachment.

The company says all these new additions are designed to make the job significantly easier for the farmer, while the strength and construction of the unit is another standout feature.

After two weeks of intensive use Mr Binns says the build quality of the trailer is a big plus point in his mind.

He says while the aluminium hurdles have plenty of ‘meat' to them, hopefully preventing issues such as cracking which he has experienced with competitor models, their heft can mean pulling them around the back of sheep quickly can be a struggle.

Helpfully, the hurdles feature rounded corners, so can be dragged across the field in groups of three and into position without too much friction.

Build quality

From a build quality point of view, Mr Binns says: "The craftsmanship in the welding and construction of the panels, which use profiled bars, is to be admired, hopefully ensuring a long service life."

The other big advantage in his eyes over the previous model is the top rail inside the hurdles has been replaced with vertical bars. He says sheep move easier through a system with this style of hurdle as they can see more through them, and if they do start climbing or jumping no harm is going mto come to them.

Where he is not so enamoured with the design is in the backing gate of the crowding pen. These gates, which hang within their own frame, have horizontal bars, rather than vertical ones.

This is a big issue for Mr Binns who fears in flighty flocks legs could become caught.

He says: "If ewes decide to start climbing or jumping as they get near these gates, there is a chance of legs getting trapped."

We think a quick fix would be covering them in some thin stock board. While discussing the gates he also points out it requires some skill and concentration to get the drop pin to latch with the framework of the gate, as there is no stopping plate or pin guide to stop the gate swinging all the way through.

Likewise, for his 700-strong Swaledale flock, Mr Binns says the shedding gates would need to be boarded up as horns could become entangled with the galvanised steel bars. However, the guillotine gate at the front and rear of the race were a good addition according to Mr Binns, proving easily operable from the rear of the race by a rope.

The framework that the guillotine gates slide up and down in is removable for transport and is simply attached with a pair of drop pins which also hold the drawbar on for transport. Mr Binns says the height of the frame is perfect to put a rope across, enabling a shearing machine to be dragged the length of the race during summer months.

An area which scored highly in Mr Binns' book was the integration of a weigh crate into the main body of the race. Using a Tru-Test weighing platform and screen, the system integrated with the recessed floor of the trailer, near seamlessly.

Mr Binns was impressed with the fit, and noted how the sheep continued to flow into the trailer race, unlike other systems where the necessary step up restricts sheep flow.

Also, as the system only used one weigh bar, it was roughly half the price of other systems which used two, an added bonus for Mr Binns.

The addition of a jockey wheel, while not revolutionary, certainly helped hitching the unit onto the farm's UTV says Mr Binns.

"This is the first trailer I have used with a jockey wheel on. It makes hitching up a lot easier, especially if you are on your own, so I may look at retrofitting one onto my existing trailers."

Fastened

Mr Binns says the trailer towed well and the lightboard was securely fastened to the trailer by linch pins, rather than just being tied on.

In fact everything was securely fastened down and double pinned for safety on the road.

One criticism Mr Binns had of the trailer was the requirement to remove the wheels from it to do anything with the sheep. Unlike his other trailers, which could be partly used with the wheels still attached, removing the hurdles had to be done with the wheels disconnected.

However, from arriving in the field, to bringing the first sheep into the holding pen, setup took just 30 minutes, which Mr Binns says is as fast as his other trailers.

FG VERDICT

OVERALL, the new features of the mobile race trailer impressed Mr Binns, but there are still a few areas for refinement.

He says giving farmers a wider choice of hurdles and types of race before the main trailer race would be good.

The electric winch, while a nice thought, is not practical in its current form, but has potential.

The build quality and quantity of metal in the hurdles and trailer is his overriding positive for the unit, especially as he says he uses his nearly every day of the year, so needs to stand the test of time.