Adopting Controlled Traffic Farming (CTF) could help reduce soil compaction risk and boost yields by up to 10.5% while also reducing nitrous oxide emissions.

Grassland farmers could benefit from adopting an ‘arable mindset' and controlling the movements of machinery across fields as a means of limiting compaction and maximising grass yields.

This is according to Dr Paul Hargreaves, grassland researcher for SRUC, who has just completed a three-year study looking at CTF on silage ground.

His results show grassland farmers could expect a yield increase of 8.5-10.5% by following a CTF system, while nitrogen use efficiency will also be improved.

He says there are some key reasons why compaction should be avoided:

- Prevents water infiltration - resulting in wet soils which take longer to drain.

- Reduces soil pore spaces - so earth worms can't do their job.Oxygen needs to get into the soils and carbon dioxide needs to escape.This is compromised if soils are compacted

- Reduces nitrogen utilisation - anaerobic soils will reduce the mineralisation of key nutrients such as nitrogen

- Increases nitrous oxide production (a greenhouse gas) - this gas is a product of denitrification, a biological process by which some nitrate in the soil is reduced to nitrous oxide.The rate of denitrification is increased in compacted soils, because of the lack of air as they're denser and wetter for longer

- Reduces nutrient availability - such as phosphate

part 2

Rather than driving anywhere on a field, CTF means machines follow set wheel marks which run parallel to the line of trajection and then around the headland.

"It's about trying to control the movements of machinery around a field to limit the area they cover and running all machinery along similar wheelings.

It's trying to think of grass as an arable crop," says Dr Hargreaves.

SRUC trial work found that about 83% of a field cut three times using a forage harvester, with slurry applied, will be covered in wheelings on a traditional system.

These wheelings will suffer from soil compaction and therefore reduced yields.

On a CTF system, the area covered in wheelings will reduce to about 19%.

Think about Tyre Size

Opting for taller, narrower tyres could be a good way of reducing your working width, without compromising on compaction risk.

James Duggleby, of Krone, says a few centimetres saving on working width can make all the difference when trying to manoeuvre machinery along narrow lanes and gateways.

He says selecting a narrow tyre, that is also tall, helps limit compaction problems as the larger circumference means there is more length in ground contact.

For example:

- An 800mm/70 R38 tyre has a footprint of 2.114m2 and a transport width of 3.3m

- A 710/70 R42 tyre has a footprint of 2.208m2 and a transport width of 3.2m So, a 10cm saving in working width does little to impact on footprint and compaction risk.

Trial

Trial

The three-year trial at SRUC looked at long-term performance of a perennial ryegrass and red clover ley, which was established at the start of the trial.

They looked at different nitrogen application rates and compared CTF and non-CTF.

In the non-CTF strips, machinery was driven wherever they wanted.

On the CTF strips, the fertiliser and slurry spreaders, mower, tedder, rake and forager, all followed a nine-metre working width.

Dr Hargreaves was keen to see the damage caused to the wheelings on the CTF system over the three years.

Although there was an increase in soil bulk density and reduced porosity, he says there was ‘limited damage' and no issues with water run-off from these areas.

"So far, we've seen a reduction in yield on those wheelings and the red clover has disappeared entirely, but the perennial ryegrass is still there," he says.

He believes this is not a huge issue on a three-year red clover ley as the issue could be addressed as part of reseeding.

If a farm was doing CTF on a five to six-year perennial ryegrass and red clover ley, some kind of mitigation work would be needed on these wheelings, such as sward lifting.

Wheelings would then need to be shifted across in the next season so improvement work was not compromised.

Overall, Dr Hargreaves says focusing traffic in set areas helps minimise overall field damage.

"You are reducing the structural damage to soils so you are potentially maintaining drainage and the quality of the soil.

And you know where the damage is on the field so you can deal with it specifically," he says.

Operating Controlled Traffic Farming

To operate CTF, Dr Hargreaves suggests thinking about the following:

-

What is the smallest working width of all your machinery?

If your smallest working width is nine metres, all equipment needs to work within this. This includes the slurry spreader, tedder and mower, etc.This means machinery will have to work along three-metre-wide tyre tracks in the field. -

Split up fields

Divide the width of each field by the working width of your machinery.If a field is 135 metres wide and your smallest working width is nine, split it into 15 lines. If you end up travelling more on certain areas of the field, make a note of it and target soil improvement work in this area. -

Use technology

Dr Hargreaves believes GPS and auto-steering technology is essential to do CTF properly. However, as a minimum he thinks GPS is essential.This will increase accuracy. "Newer tractors being sold and equipment used by contractors often have GPS. This technology is becoming increasingly common place so it could be a case of just using the technology you've already got," he says. -

Use marker posts

If technology is not an option, consider using sight posts or positions in the field so machinery is driven in a particular route. All individual tractor drivers will need to pay care and attention. -

Pay attention during carting

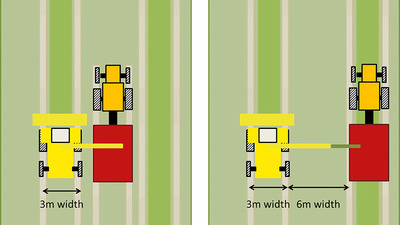

The distance between the forage harvester and silage trailers will increase with CTF - potentially to six metres. This means the team will have to work steadily. Also, consider using high-sided trailers and not filling trailers all the way to the top

Grassland and Silage 2020

Want to continue reading the series? Click the links below for further information.

- Limiting compaction at silage-making

- Reducing soil compaction with CTF principles

- Managing clover in grazing swards

- Controlling weeds in clover swards

- Creating a more sustainable system by maximising milk from forage

- Tackling ammonia emissions

- Spray weeds in autumn for best control

- How to get the best from a new ley

- Ultra-Low Volume saves time at silage-making

- Additive safeguards silage quality

- Additive is a must on multi-cut

- Tedding and raking are backbone to silage success

- Control quality and costs by producing home-grown haylage